Learn Inventory Planning for Bulky Equipment like Trolleys Now

Table of Contents

Introduction

For suppliers serving Healthcare MSMEs, managing inventory planning for bulky equipment like medical trolleys, hospital beds, or examination couches is a constant balancing act between meeting demand and controlling storage costs.

These items take up significant warehouse space, require careful handling, and are often ordered in bursts based on hospital expansions or clinic openings.

This guide breaks down the strategies, forecasting methods, and supplier clinic coordination practices that can help you maintain optimal stock levels without tying up too much capital or space.

What Factors Should Suppliers Consider When Planning Inventory for Bulky Medical Equipment like Trolleys?

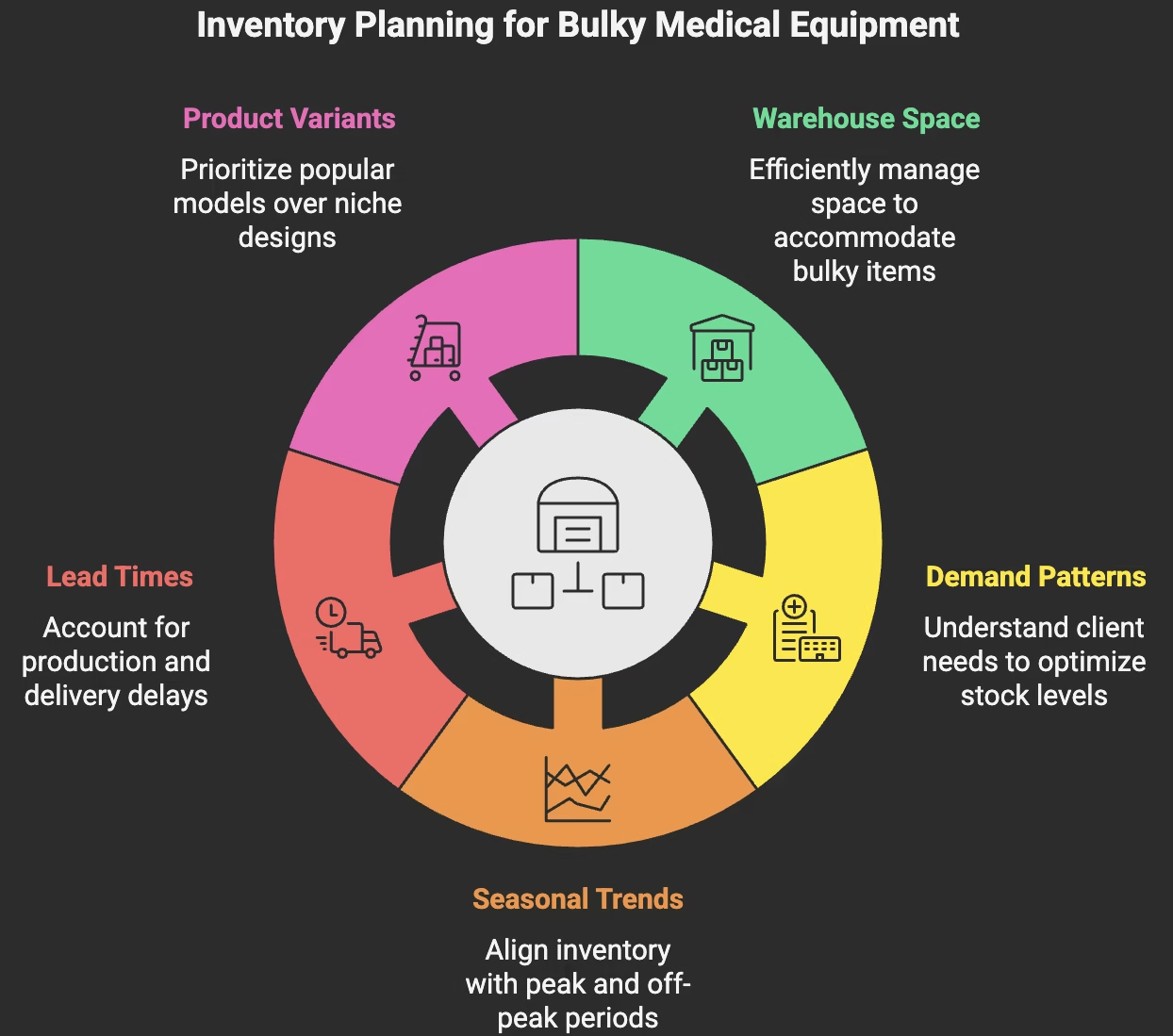

When handling inventory planning for bulky equipment, suppliers must factor in both operational and market variables:

- Available Warehouse Space

- Bulky medical trolleys can consume 20–30% more floor area compared to smaller consumables.

- Plan stacking methods or use vertical racks to free up space.

- Bulky medical trolleys can consume 20–30% more floor area compared to smaller consumables.

- Demand Patterns by Client Type

- Small clinics order in single units or small batches.

- Hospitals may place large orders when opening new wards or upgrading facilities.

- Small clinics order in single units or small batches.

- Seasonal Trends

- Government tenders and new hospital projects often peak at the start of the financial year (April–June in India).

- Festival or budget seasons sometimes delay purchases from MSMEs.

- Government tenders and new hospital projects often peak at the start of the financial year (April–June in India).

- Lead Times from Manufacturers

- Imported trolleys can have 45–60 day lead times, while domestic production may take 10 –15 days.

- Imported trolleys can have 45–60 day lead times, while domestic production may take 10 –15 days.

- Product Variants

- Consider stocking fast-moving types like stainless-steel instrument trolleys over niche designs unless pre-ordered.

- Consider stocking fast-moving types like stainless-steel instrument trolleys over niche designs unless pre-ordered.

Example: A supplier in Gujarat reduced idle stock by 25% by categorizing inventory into “fast-moving” and “on-order only” SKUs based on past sales.

How Can Suppliers Avoid Overstocking Bulky Healthcare Equipment and Reduce Storage Costs?

Overstocking leads to blocked capital, warehouse congestion, and potential damage to items. Here’s how to control it:

- Adopt a Just-in-Time (JIT) Approach – Keep minimal stock on hand and align orders closely with confirmed client requirements.

- Implement Order Scheduling – Coordinate with clinics and hospitals to schedule deliveries over multiple weeks instead of all at once.

- Use Shared Warehousing – Collaborate with logistics providers that offer short-term storage space for large deliveries.

- Track Dead Stock – Identify slow-moving SKUs and offer clearance discounts to free up space.

- Negotiate Flexible Manufacturing Slots – Partner with manufacturers who can prioritize production on short notice to reduce the need for high safety stock.

Pro Tip: Warehouse layout optimization, such as grouping trolleys by type and order priority, can free up to 15% of usable space.

What Are the Best Demand Forecasting Methods for Medical Trolleys in Small Clinics and Hospitals?

Accurate demand forecasting is the backbone of inventory planning for bulky equipment.

For healthcare MSMEs, you can combine:

- Historical Sales Data Analysis

- Track monthly and quarterly orders from repeat clients.

- Identify patterns around hospital expansions, tender wins, or seasonal spikes.

- Track monthly and quarterly orders from repeat clients.

- Market Trend Monitoring

- Keep an eye on healthcare infrastructure projects in your region.

- Monitor AYUSH, NABH, and state government announcements for funding that could trigger equipment purchases.

- Keep an eye on healthcare infrastructure projects in your region.

- Client Order Pipelines

- Maintain informal communication with key clients to know about upcoming expansions or new branches.

- Maintain informal communication with key clients to know about upcoming expansions or new branches.

- Inventory Turnover Ratios

- Measure how many times stock is sold and replaced in a given period low turnover indicates overstock risk.

- Measure how many times stock is sold and replaced in a given period low turnover indicates overstock risk.

Example: A Delhi-based supplier used 3 years of clinic opening data to forecast Q2 demand spikes, aligning procurement to match the trend and cutting storage costs by 18%.

How Can Suppliers Balance Bulk Purchase Discounts with Limited Storage Capacity?

Bulk orders from manufacturers often come with attractive discounts but require large storage space posing a challenge for suppliers of bulky healthcare items.

Strategies to Balance Both:

- Vendor Agreements with Staggered Delivery – Negotiate to receive bulk-purchased items in smaller shipments over time.

- Consignment Stock – Arrange for the manufacturer to hold your stock until needed.

- Forward Financing – Use purchase order financing or bank credit lines to buy in bulk without exhausting working capital.

- Pre-Sell Before Receiving Stock – Offer early-bird discounts to clinics for items not yet in your warehouse.

Example: A supplier in Bengaluru secured a 12% discount on 100 trolleys by splitting deliveries into four monthly batches, reducing storage pressure.

What Role Does Supplier–Clinic Communication Play in Accurate Inventory Planning for Bulky Medical Equipment?

For healthcare MSMEs, strong communication between suppliers and buyers can be the difference between optimal stock levels and overstock losses.

- Pre-Order Commitments – Encourage clinics to place orders in advance, even if delivery is scheduled later.

- Lead Time Transparency – Keep clients informed about manufacturing and shipping times, especially for imports.

- Regular Check-Ins – Monthly follow-ups can reveal upcoming needs before formal purchase orders are raised.

- Feedback Loops – Use post-delivery feedback to refine stock planning and understand usage cycles.

Why it Works:

Good communication helps suppliers adjust production schedules, reserve warehouse slots, and allocate resources more effectively, preventing both stockouts and excess inventory.

Conclusion

Mastering inventory planning for bulky equipment like trolleys is critical for suppliers serving healthcare MSMEs.

By understanding demand patterns, avoiding overstocking, applying accurate forecasting methods,

By balancing bulk discounts with storage realities and maintaining strong client communication, suppliers can optimize both costs and customer satisfaction.

The goal is not just to store equipment but to move it efficiently from manufacturer to clinic with minimal delays and expenses.

Frequently Asked Questions (FAQ)

Q1: What’s the biggest challenge in stocking bulky healthcare equipment?

A: Space constraints and the high cost of storing slow-moving items.

Q2: How can I predict when clinics will need new trolleys?

A: Track clinic expansion projects, monitor seasonal sales patterns, and maintain direct communication with clients.

Q3: Is it worth buying in bulk to get discounts?

A: Yes, but only if you can arrange staggered deliveries or consignment storage to avoid warehouse overload.

Q4: How can I reduce warehouse costs for large equipment?

A: Use shared warehousing, optimize layout, and limit stock to high-demand SKUs.

Q5: Does better communication with clinics really improve inventory planning?

A: Absolutely it allows you to align production, avoid last-minute shortages, and reduce excess inventory.

Also Read,

- The Ultimate Guide: Working Capital Loans for Small Business (MSMEs) in 2025

Understanding the Impact of Payment Terms on Working Capital for Clinics

How Poor Inventory Management Hurts Working Capital in Pharmacies.

Want a Better Business Credit Score? Small Pharmacies Can Now Use UPI & Cards to Build It

Want a Better Credit Score? Use Small Daily Payments to Build Your CBIL (For Clinics & Pharmacies)

Case Study:How a Small Clinic Improved Its Working Capital Management